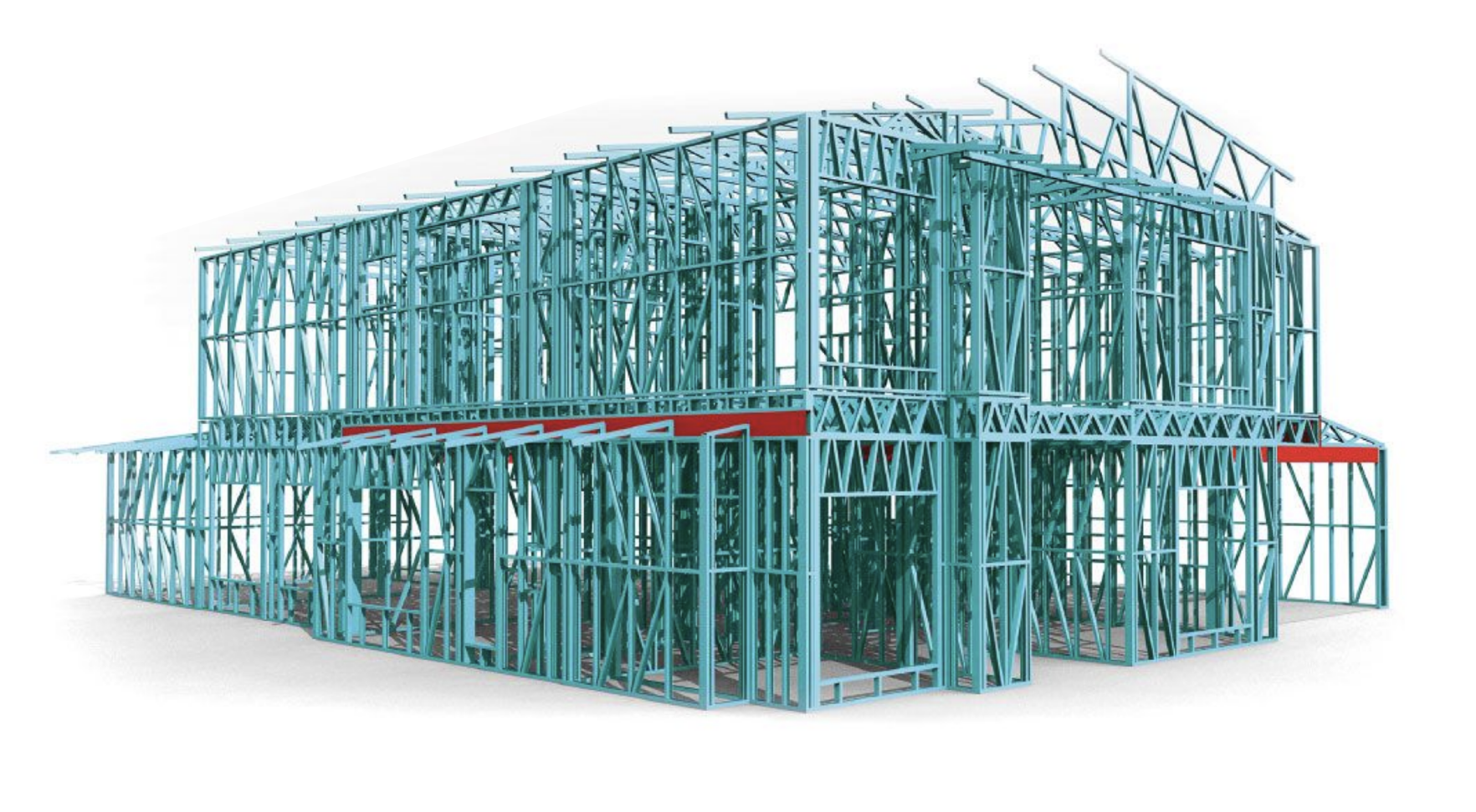

LOAD BEARING AND NON-LOAD BEARING APPLICATIONS

Fully load-bearing and non-load bearing panel options are available with a variety of service provisions to include flat packed panels, fully assembled panels and a full design service.

The Primaframe system is a unique fully engineered CALEDAN design which we firmly believe takes into account the vagaries of the UK construction sector. The versatility of our rolling mills allow us to produce fully framed panels in 100 - 250mm section widths and in gauges between 1mm and 2mm thick. This versatility allows us to provide a variety of solutions for both single storey and multi storey constructions with wall widths to suit both structural and architectural requirements.

CONSULTANCY

We can provide advice and support throughout the course of your project: - Inception, feasibility, design, manufacture, supply and warranty.

KEY POINTS

- Feasibility

- System Type

- Procurement Route

DESIGN

We offer varying levels of design support dependant on your project needs:- indicative design(feasibility), full design option one and full design option two.

KEY POINTS

- Level of Design Required?

- Information Required

MANUFACTURE

We manufacture all of our sections ‘in-house’ for complete quality control and confidence. We can offer bespoke section sizes subject to requirements

KEY POINTS

- Type of Section

- Size of Section

- Gauge of Section

ASSEMBLE

Caledan can offer a fully assembled panelised solution and apply sheathing boards if necessary.

KEY POINTS

- Primaframe or Stud & Track

- Assembled or Unassembled

SUPPLY

We deliver nationwide, and our lead time can be agreed to suit your schedule.

KEY POINTS

- Lead in Time

- Delivery Restrictions

- Vehicle Type

INSTALL

We can help put you in touch with an installer in your area if required.

CALEDANS steel frame systems are manufactured from high quality locally sourced steel.

Innovation in off-site manufacturing at our cold steel rolling mill enables the forming of steel metal sections which can create practically any bespoke product from a vast range of profile section sizes from 100-250mm wide and in gauges between 1.00-2.00mm thick.

Because CALEDAN can be a single source for the design and manufacture of complete SFS systems, we are able to react quickly and efficiently and deal with any changes without delay.

COMPARISON TO MASONRY

- Steel has one of the highest strength to weight ratios of any building material inc. masonry.

- Steel facades can be erected far more quickly than traditional masonry, particularly when considering the vagaries of the UK climate.

- The building to a large degree can be weather proofed at an earlier stage allowing internal activities to progress thereby reducing programme times and expensive preliminary costs.

- Steel Facades can be considerably lighter than masonry, sometimes reducing formation and foundation requirements.

- Steel facades can provide far more accuracy in line and level than can be achieved in masonry or timber.

- Steel being more ductile than concrete will provide more resistance to structural cracking.

COMPARISON TO TIMBER

- Steel has one of the highest strength to weight ratios of any building material inc. Timber

- Steel is roll formed into uniform, precise shapes with exact tolerances for consistent material quality.

- Steel Studs are straight. They don’t warp, twist, bow, split or have knots, which means straight walls and square corners.

- Steel is dimensionally stable and will not shrink like wood, eliminating nail popping and wall cracking.

- Steel does not rot, promote mould or mildew and is impermeable to vermin, termites and insects.

- Steel framing can reach far greater spans than traditional or engineered timber, providing larger open spaces.

- Stick for Stick, steel can weigh 50% less than timber.

- Steel can be temporarily stored externally without fear of water absorbtion.

- Steel Framing is not combustible and will not add fuel to a fire.

OVERVIEW & BENEFITS OF PRIMAFRAME

- Caledan Primaframe sections can be supplied in a variety of widths between 100mm and 250mm wid

- Gauges for the sections range between 1mm to 2mm.

- Suitable for fully load bearing and non-load bearing applications.

- Full stand-alone structural systems and complete constructions without the requirement for a hot rolled steel or concrete frame.

- Our unique rolling mill tooling arrangement allows for a flush finish wall profile which facilitates flush and flat fixing of sheathing boards or plasterboard linings.

- Window and door openings are easily designed and accommodated.

- A variety of bracing solutions can be formed from the stud section and be incorporated within the wall structure.

- CALEDAN can supply primaframe in either ‘flat packed’ form or fully assembled panels. In either case fully identified Panel assembly drawings are provided.

- Lighter and much faster than traditional masonry construction and also typically lighter than timber frame alternatives.

- Reduced maintenance and far less shrinkage than traditional or timber frame construction.